SM Series

在此写入描述

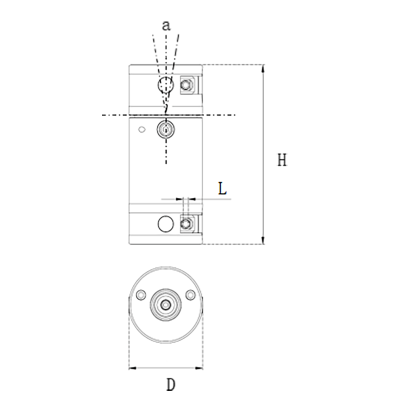

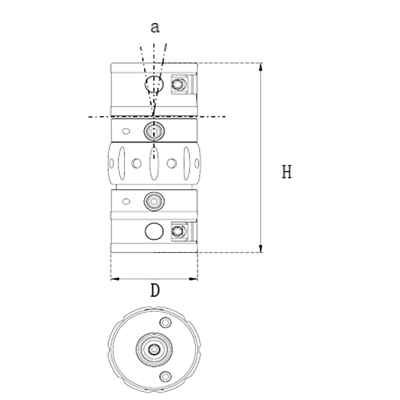

SM-A

| Name | ID | Outer Diameter (D) | Height (H) | Yaw Angle (a) | Hexagon Width (L) | Hexagon Torque | Weight |

|---|---|---|---|---|---|---|---|

| M08-SM-A | M08-SM-0 | 75mm | 180mm | ±3° | 5mm | 12Nm | 5Kg |

| M12-SM-A | M12-SM-0 | 85mm | 200mm | ±3° | 6mm | 20Nm | 7.5Kg |

| M16-SM-A | M16-SM-0 | 105mm | 260mm | ±3° | 8mm | 45Nm | 15Kg |

Applications

Locate the origin of workpiece in the X/Y plane.

Suitable for the primary processing of heat-treated wprkpiece and casting workpiece.

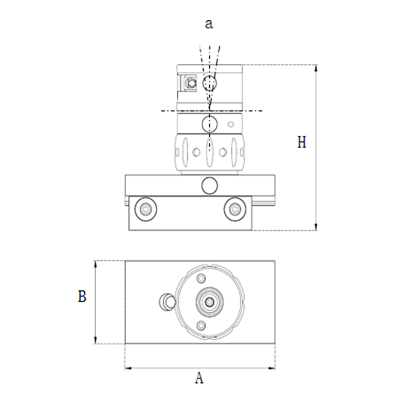

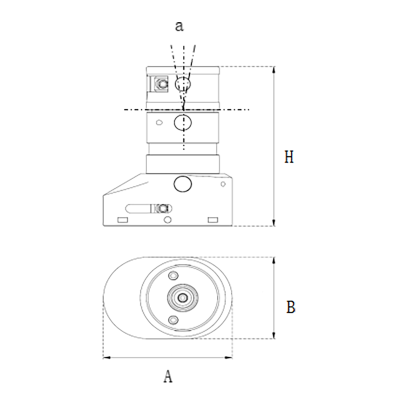

SM-B

| Name | ID | Length (A) | Width (B) | Height (H) | Moving Range in X/Y Axis | Yaw Angle (a) | Hexagon Width (L) | Hexagon Torque | Fine-tune Method in Z Axis | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| M08-SM-B | M08-SM-LXY-MZ | 195mm | 90mm | 180±5mm | -5_+30mm | ±3° | 5mm | 12Nm | 手动 | 10Kg |

| M12-SM-B | M12-SM-LXY-MZ | 195mm | 100mm | 200±5mm | -5_+30mm | ±3° | 6mm | 20Nm | 手动 | 13.5Kg |

| M16-SM-B | M16-SM-LXY-MZ | 220mm | 120mm | 260±5mm | -5_+30mm | ±3° | 8mm | 45Nm | 手动 | 24Kg |

Applications

Axially locate the origin of workpiece(X or Y axis).

It has fine-tuning function to achieve height leveling with the origin.

Suitable for the primary processing of heat-treated wprkpiece and casting workpiece.

SM-C1

| Name | ID | Length (A) | Width (B) | Height (H) | Translation Range on XY Plane | Yaw Angle (a) | Hexagon Width (L) | Hexagon Torque | Fine-tune Method in Z Axis | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| M08-SM-C1 | M08-SM-PXY-MZ | 140mm | 95mm | 180±5mm | -5_+40mm | ±3° | 5mm | 12Nm | 手动 | 7Kg |

| M12-SM-C1 | M12-SM-PXY-MZ | 150mm | 105mm | 200±5mm | -5_+40mm | ±3° | 6mm | 20Nm | 手动 | 10Kg |

| M16-SM-C1 | M16-SM-PXY-MZ | 170mm | 125mm | 260±5mm | -5_+40mm | ±3° | 8mm | 45Nm | 手动 | 19Kg |

Applications

Clamping by using screw hole or straight hole in any position on the workpiece.

It has fine-tuning function to achieve height leveling with the origin.

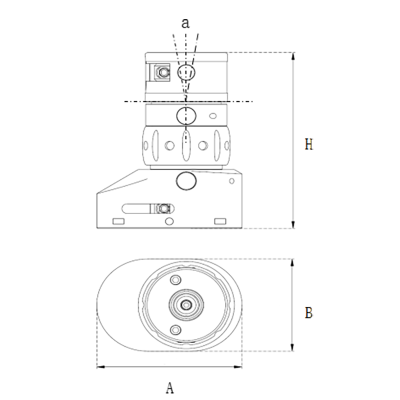

SM-D1

| Name | ID | Length (A) | Width (B) | Height (H) | Translation Range on XY Plane | Yaw Angle (a) | Hexagon Width (L) | Hexagon Torque | Fine-tune Method in Z Axis | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| M08-SM-D1 | M08-SM-PXY-AZ | 140mm | 95mm | 180(0_-10mm) | -5_+40mm | ±3° | 5mm | 12Nm | 自动 | 7Kg |

| M12-SM-D1 | M12-SM-PXY-AZ | 150mm | 105mm | 205(0_-10mm) | -5_+40mm | ±3° | 6mm | 20Nm | 自动 | 10Kg |

| M16-SM-D1 | M16-SM-PXY-AZ | 170mm | 125mm | 265(0_-10mm) | -5_+40mm | ±3° | 8mm | 45Nm | 自动 | 18Kg |

Applications

Used as the supplementary clamping of A/B/C1, to improve the clamping strength.

Automatically height adaption to reach the same height as the origin.

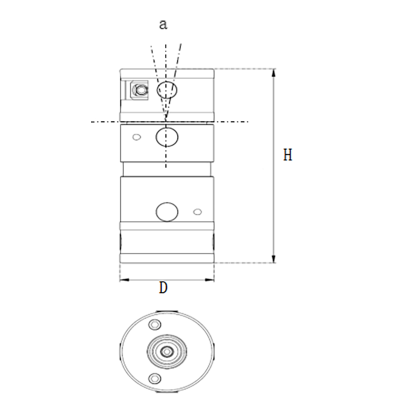

SM-C2

| Name | ID | Outer Diameter (D) | Height (H) | Yaw Angle (a) | Hexagon Width (L) | Hexagon Torque | Fine-tune Method in Z Axis | Weight |

|---|---|---|---|---|---|---|---|---|

| M08-SM-C2 | M08-SM-MZ | 75mm | 180±5mm | ±3° | 5mm | 12Nm | 手动 | 5Kg |

| M12-SM-C2 | M12-SM-MZ | 85mm | 200±5mm | ±3° | 6mm | 20Nm | 手动 | 7.5Kg |

| M16-SM-C2 | M16-SM-MZ | 105mm | 260±5mm | ±3° | 8mm | 45Nm | 手动 | 15Kg |

Applications

Suitable for clamping when the process hole is aligned with the reference hole of the reference plate.

It has fine-tuning function to achieve height leveling with the origin.

SM-D2

| Name | ID | Outer Diameter (D) | Height (H) | Yaw Angle (a) | Hexagon Width (L) | Hexagon Torque | Fine-tune Method in Z Axis | Weight |

|---|---|---|---|---|---|---|---|---|

| M08-SM-D2 | M08-SM-AZ | 75mm | 180(0_-10mm) | ±3° | 5mm | 12Nm | 自动 | 5Kg |

| M12-SM-D2 | M12-SM-AZ | 85mm | 205(0_-10mm) | ±3° | 6mm | 20Nm | 自动 | 7.5Kg |

| M16-SM-D2 | M16-SM-AZ | 105mm | 265(0_-10mm) | ±3° | 8mm | 45Nm | 自动 | 15Kg |

Applications

Suitable for clamping when the process hole is aligned with the reference hole of the reference plate.

Used as the supplementary clamping of A/B/C2, to improve the clamping strength.

Automatically height adaption to reach the same height as the origin.

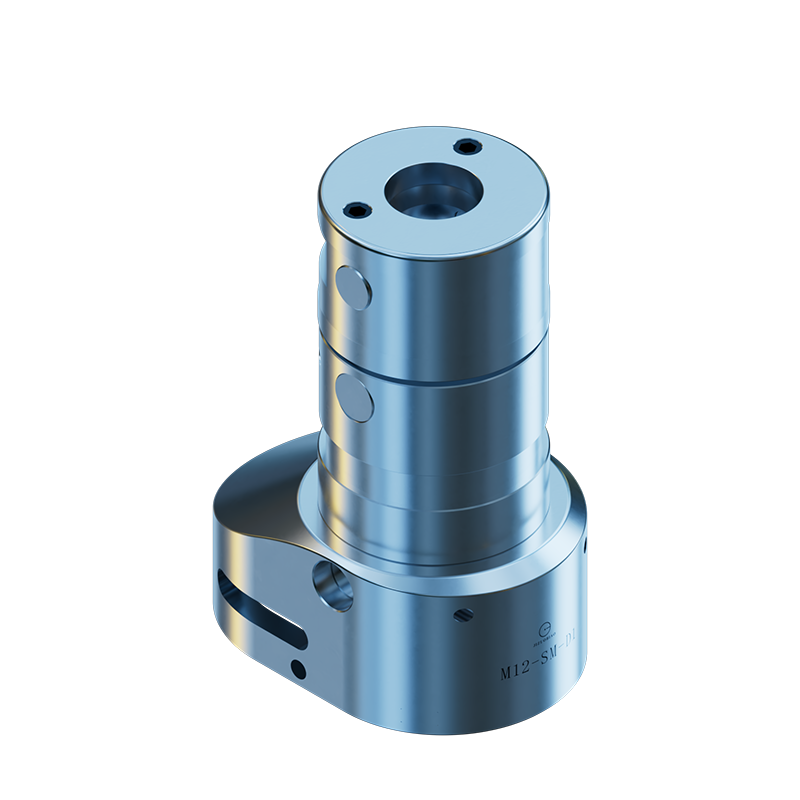

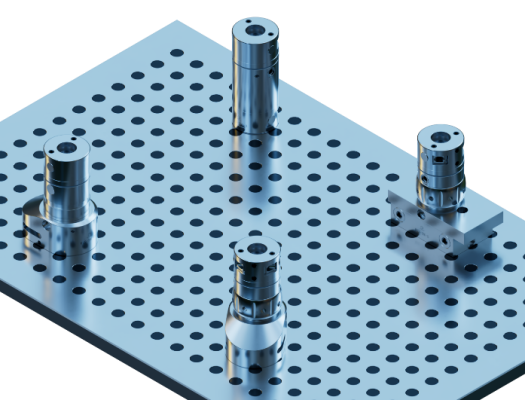

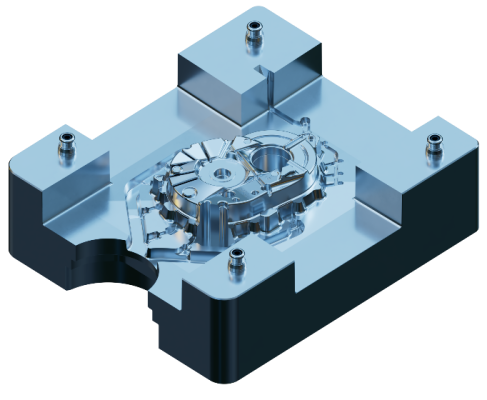

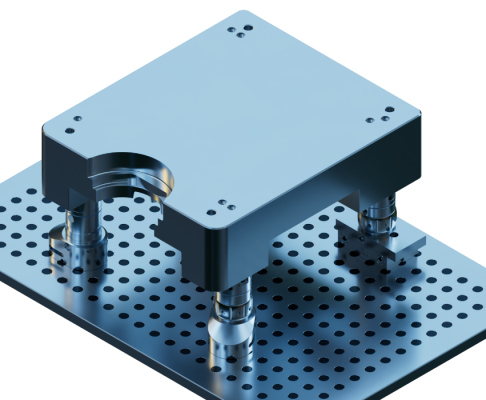

Case

SM Series Module

Clamping can be done by using screw hole or straight hole in any position on the workpiece.

Height, perpendicularity, flatness and parallelism fine-tuning can be achieved.

One-time adjustment, long-term mass production, perfect alternative to specific clamping tool.